Tink - A Series 1 Story - Pt. 2

The other week I left you with the cheery news that, while manoeuvring Tink around to inflate her tyres before the MOT, her steering box snapped clean in half. After much grunting with the Hi-Lift jack to get her shoved back into the yard, I did the only sensible thing: ordered a pizza, opened a bottle of wine, and sulked.

“Now then,” I pondered a couple of days later, “where the ‘eck am I going to find a 1955 steering box?”

All the usual suspects came up blank. Eventually, a rummage through the Series One Club’s list of parts suppliers led me to Red Dragon Restorations. To my relief, they had one.

When the ‘new’ steering box arrived, it came with instructions from Red Dragon’s owner, Stafford Dovey. They sounded straightforward enough: strip the steering surround, undo two bolts in the footwell, three horizontal bolts on the chassis bracket, one more on the wing bracket, break the ball joint, then feed the whole thing through the footwell. Refitting was simply the reverse.

Sounds easy, doesn’t it? Well, it wasn’t. It was a filthy, awkward job. That said, having done it once, I reckon I could now do it in half an hour. Funny things, old Land Rovers.

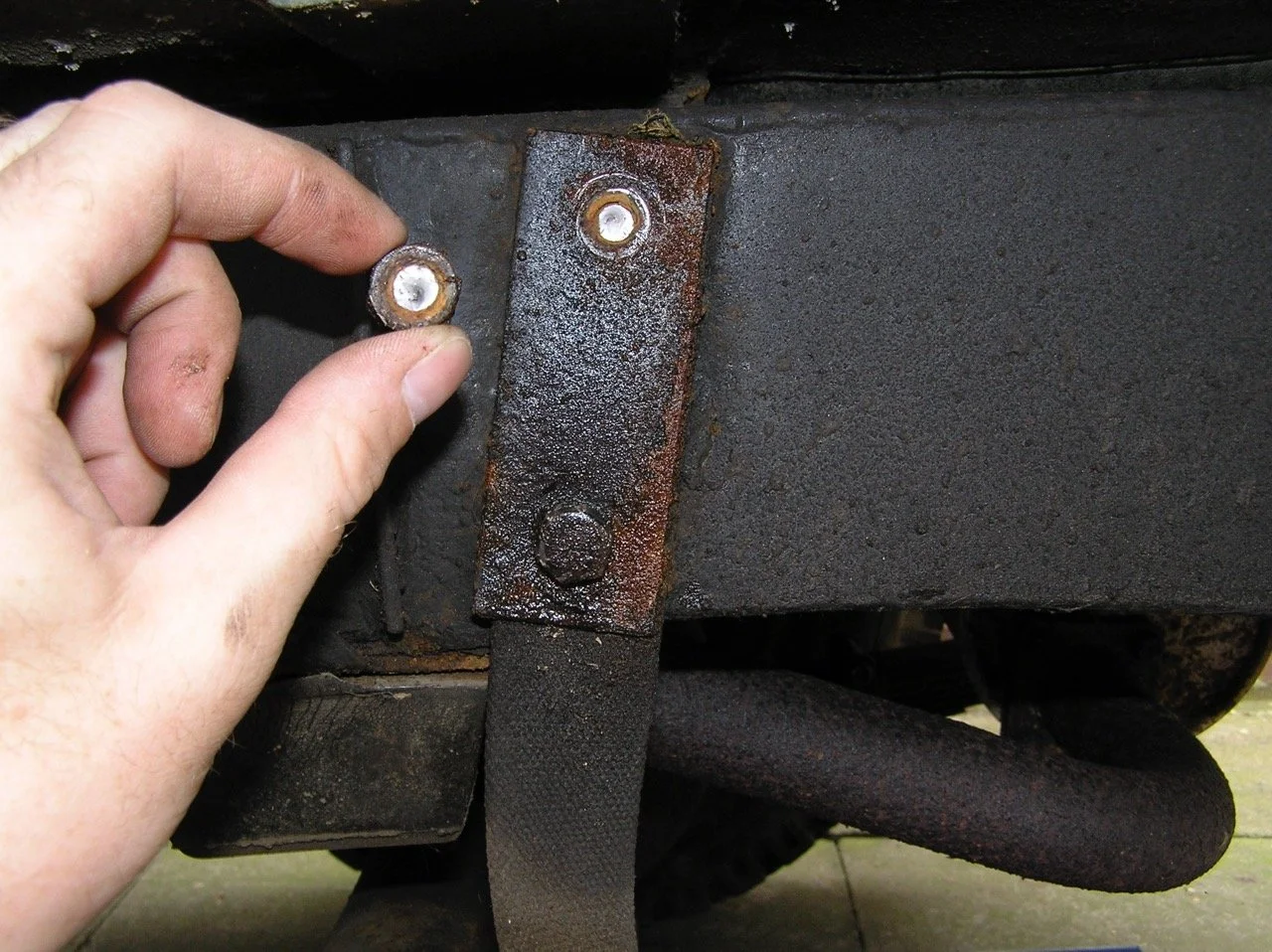

With the old unit in the vice, I used my mate Chris’s hydraulic bearing puller and a good soaking of WD-40 to remove the drop arm and chassis bracket, then transferred them to the replacement box. I also fitted a new ball joint onto the steering arm.

By now it was dark, so with my head torch on, I slid the new steering box back up through the wheel arch and into place, fumbling with bolts in the footwell while wishing for longer arms. Brackets secured, column reattached, all looked good. By morning, all I had to do was connect the ball joint, fill with oil, and move on to the MOT jobs.

At least that was the plan.

The next day, after returning Chris’s puller (important detail), I wriggled underneath in my ‘Land Rover clothes’ and went to fit the ball joint. No chance. It simply wouldn’t go. That’s when I realised I’d done the order wrong. The drop arm needed fitting first.

Cue another round of pulling the box out, borrowing Chris’s puller again, removing the arm again, swearing again… and then refitting the lot in the correct order. This time it worked. Oil in, arms bolted, everything tight — success at last.

Next jobs: get the windscreen wiper working, replace the snapped axle strap, and give her a service. But then reality set in: dark nights, rain every day, a dodgy back, too much work, and… let’s be honest… sheer apathy. So Tink sat untouched for the next five months.

By March, lighter evenings and a bit of sun rekindled my enthusiasm. I remembered that spluttering issue whenever I pressed the accelerator — a little “psssst” followed by a brief stall. Since it had been twenty-odd years since I last fiddled with an ignition system, I invited my mate Barny over.

Nothing looked drastically wrong, but most of the ignition parts were a mishmash of old and new. Fifty quid later, Tink had fresh leads, dizzy cap, plugs, coil, rotor arm, and points. It helped, but she was still “psssst-ing.”

Right then, fuel system. She’d been started occasionally over the years but not properly driven for five, so maybe things were gummed up. I cleaned the sediment bowl (seemed a good place to start), stripped the fuel pump, fitted a new diaphragm. No joy.

The next suggestion, from an experienced Series One owner, was: “Take the carb off and blow it.” Not exactly the kind of intimacy I had in mind, but after removing the carb and puffing into every opening I could find — lo and behold, it worked. No more “psssst.”

With that sorted, on to the wiper. The motor was there, but no wiring. My mate Chris reckoned I needed a banana plug, so Julian handed me a couple. Once connected, the motor reluctantly came to life, though it was as much use as a chocolate teapot. A trip to Buckley Bros in Darwen sorted me with a new arm, blade, and adaptor. Woohoo, progress!

That left the axle strap. The nearside one was dangling in two bits, and the bolts had their heads snapped off. Lacking time to drill them out, I simply cut the strap off and soaked the other bolts in penetrating spray. If it’s not there, it can’t fail an MOT, right?

Final checks included strapping down the battery and cleaning the mucked-up brake light switch (it sits in a daft place just forward of the driver’s footwell). That did the trick — working brake lights again.

And so, with 37,373 miles on the clock, we trundled gently off to Simon at Horwich MOT Centre. My confidence in Tink grew with every yard, though I kept one ear out for any groans from the ‘new’ steering box.

And the result? She only went and passed.

After almost six years, my Series One Land Rover was road legal again. Driving home roofless, with the door tops off, I grinned like a Cheshire cat. One thought kept running through my mind: let the adventures begin!